- RASPBERRY PI PARALLEL PORT CNC DRIVER

- RASPBERRY PI PARALLEL PORT CNC UPGRADE

- RASPBERRY PI PARALLEL PORT CNC SOFTWARE

This project begs to differ: but notice just how heavily reinforced it is and how much of the machine is new growth. But a plotter or a laser is about as much as you’ll get out of that frame any kind of rotary tool is going to exceed its structural integrity and lead to rapid unplanned disassembly. So far my A8 works as a passably decent filament printer with PLA, ABS, TPU, and PETG, and I printed out a bracket to hold a sharpie so I can use it as a small plotter. Might even add dual extrusion as well! Who knows.

RASPBERRY PI PARALLEL PORT CNC UPGRADE

Hopefully that’ll be the last safety upgrade it needs. No thermal runaway protection? I think my toaster is more advanced than that.

I’m currently working on putting in a RAMPS board to replace the cornballer of a control board that comes with the A8. I definitely learned enough to justify the hours of labor spent. For the record, I wanted to get an A8 and improve it instead of simply buying a good printer from the get-go because it seemed like a good way to practice my CAD and mechanical design skills. It’s a fun project if you know what you’re getting into, but if you wanted to convert it to a subtractive machine I’d go out and get a welder and some scrap metal and begin from scratch instead. Also makes welding parts together with acetone a possibility if you want braces that are larger than the print bed with no hardware. ABS just for the higher glass transition temperature, to keep it from sagging next to the hot end and heated bed. I can confirm that, I needed to print about two spools of ABS worth of braces and some threaded rod supports to make my A8 even print right. Posted in cnc hacks, Raspberry Pi Tagged cnc, raspberry pi, stepper, stepstick Post navigation

RASPBERRY PI PARALLEL PORT CNC SOFTWARE

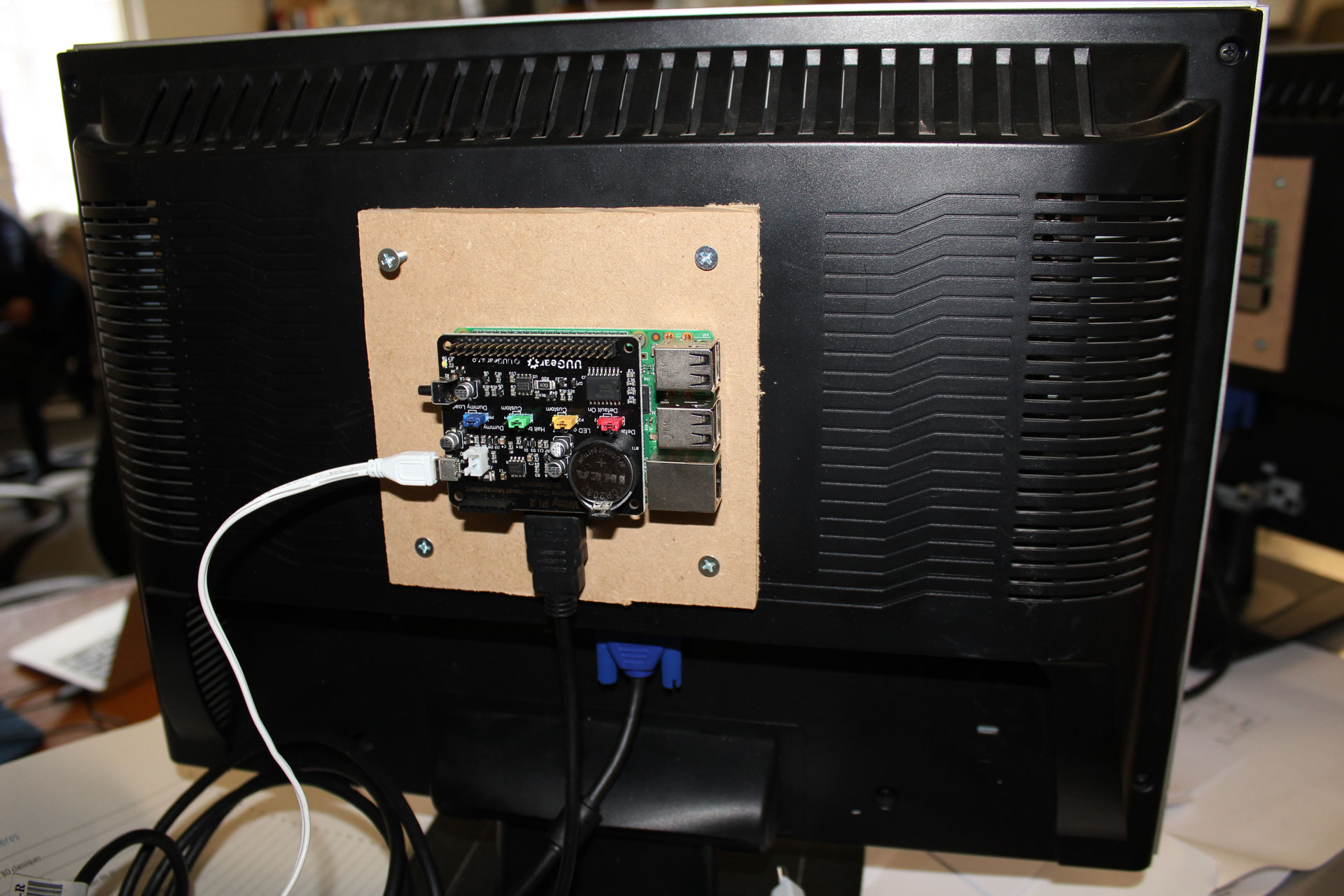

We’ve seen attempts at creating all-in-one Linux stepper controllers in the past, but the fact that anyone with a Raspberry Pi 2 or 3 (the boards this software has currently been tested on) can get in on the action should really help spur along development. Not only can you skip the control board, you could conceivably handle the machine’s user interface (either directly via a touch screen or over the network) on the same Pi. This method of direct control offers some very interesting possibilities for small, low-cost, CNC projects. These little modules connect up to a dedicated power supply and handle the considerable current draw of the steppers, all you need to do is provide them the number of steps and direction of travel.

RASPBERRY PI PARALLEL PORT CNC DRIVER

But you can wire it up directly to a stepper driver board. Of course, you can’t directly control a beefy stepper motor to the GPIO pins of a Pi. Called raspigcd, this software interprets a subset of G-Code to provide real-time control over connected steppers fast enough to drive a small CNC router. The only thing missing is the software to interpret the G-Code and command the steppers over GPIO, which thanks to, we now have. Thanks to the Raspberry Pi (and similar boards), we now have Linux computers with plenty of GPIO pins. Historically this has been something of a necessary evil, as there was really no way to directly control stepper motors with a computer fast enough to be useful. This board takes commands from a computer, often in the form of G-Code, and interprets that into movement commands to the connected stepper motors. If you’re building a CNC router, laser cutter, or even 3D printer, you’ll usually be looking at a dedicated controller.

0 kommentar(er)

0 kommentar(er)